How to ensure quality in the installation of an ULMA ventilated facade

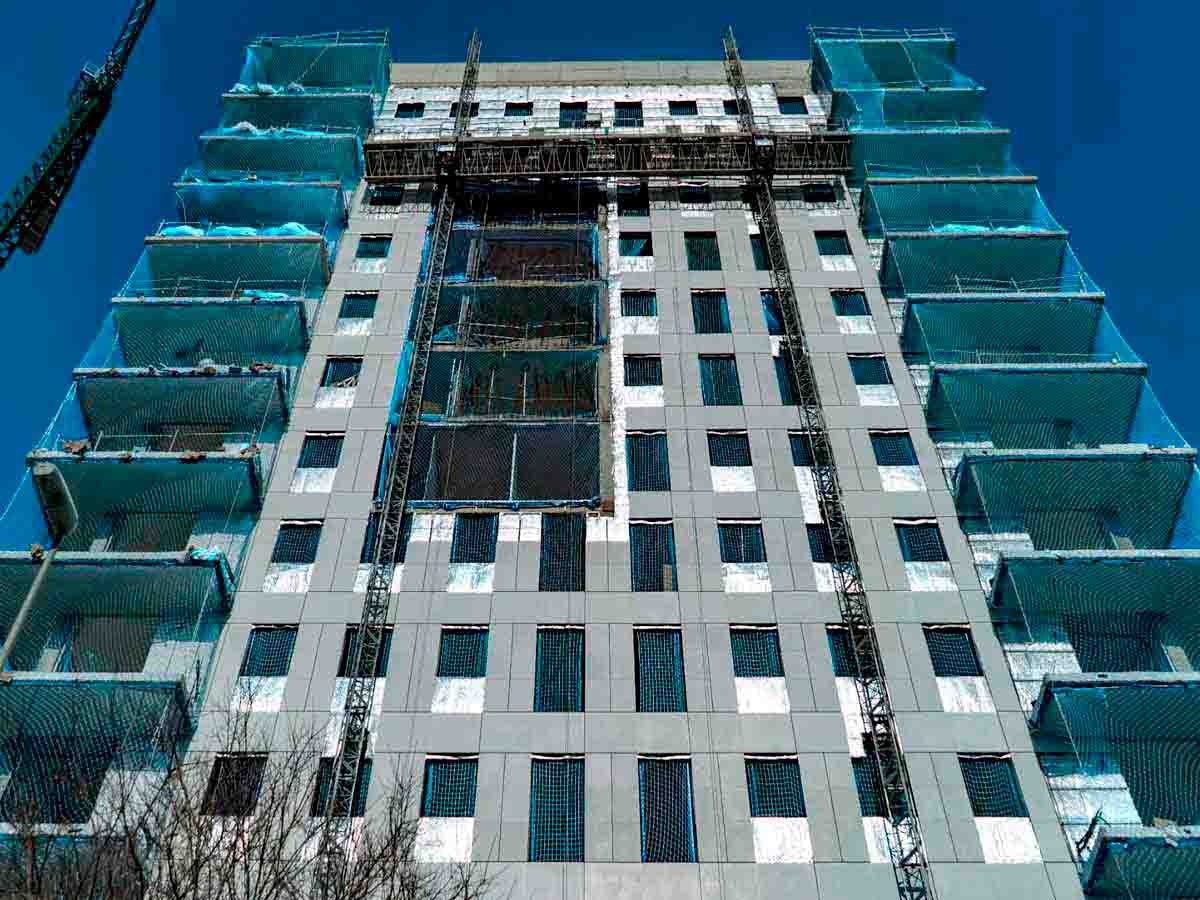

Ventilated facades are considered to be one of the best building solutions for achieving optimal thermal and acoustic insulation. ULMA ventilated facades, manufactured using Stoneo panels, offer even greater added value: increased durability or increased resistance to impact and corrosion, among other benefits. But to get the most out of these advantages, optimal installation is essential.

Here we will explain what you have to do as an architect, developer or planner to ensure the proper level of quality during the installation of our facades.

Essential aspects for installing an ULMA ventilated facade with maximum quality

The first and most important condition for ensuring the quality and durability of our products is to strictly follow the installation process described in our installation manual. The following recommendations are thus essential:

- The personnel installing the facade must have received specific training from ULMA and hold the corresponding certification.

- It is also necessary for a technician specialised in the installation of this type of facade to carry out the necessary check-up inspections during the different installation phases. The purpose of these inspections is to check and ensure that the previously defined installation parameters are being respected, as well as to correct any possible faults.

- Choose suitable anchors and install them correctly.

Anchors are essential in the structure of a ventilated facade, since unsuitable anchors or inadequate installation can reduce the durability and efficiency of the facade and even cause safety problems.

The importance of anchors in the installation of ventilated facades

Before starting the work, our ULMA ventilated facade installation protocols require an anchorage pull-out test to be conducted on the supporting walls, following the recommendations of the ETAG 020-B standard.

We also follow the recommendations of this standard to choose the type and geometry of the anchors to which the panels will be secured, taking into account the characteristics of the materials used in the base wall, both the brickwork and the type of concrete used.

At ULMA, we always use the same type of anchor for each type of base wall from the beginning of the installation, having verified, following the relevant tests, that it offers the expected results in terms of strength and safety.

Common bad practices in the installation of a ventilated facade

The most common inappropriate operations and bad practices during the installation of ventilated facades usually relate to not strictly following the guidelines in the installation manual. Specifically, the most common mistakes are:

- Failing to adhere to the fixed and flush bolting points specified in the assembly instructions.

- Forgetting to bolt the ends of the secondary profiles to the uprights.

- Failing to drill all the holes marked in the manual in the secondary profiles for water drainage.

- Sometimes failing to place the locking piece on the corner panels and next to the facade openings.

These incidents can reduce the efficiency of the installation, which is why at ULMA we always closely monitor the installation, checking each and every one of the specific points of each phase.

Optimal installation almost completely does away with the risk of detachment.

Panel detachment in a ventilated facade structure is an undesirable occurrence due to the danger it poses to the integrity of people and the material damage it can cause.

Moreover, repairing such a problem is complex and costly: it is necessary to conduct a study to find out the specific reason for the detachment, obtain measurements of the damaged panel(s), manufacture new panels and install them. This requires the use of large articulated lifting machines or suitable vertical working equipment.

For more information contact us here.

The most effective way to prevent the risk of detachment is to continuously monitor the installation of works in progress and to provide continuous, high-quality training for installation personnel.

At ULMA, we are committed to finding complete, integral construction solutions that cover the entire process, from project development to installation control and monitoring. In this way, we ensure the effectiveness, efficiency, durability and safety of our products, avoiding incidents and costly renovations at a later date.