Extention to Malaga Airport- Spain

Located 8 km from the city of Malaga, and with a location that makes it a gateway for tourism on the Costa del Sol, the Malaga airport is the 4th largest airport in Spain according to passenger numbers and flight operations, with a predominance of more than 80% of passengers arriving on international flights. This year the extension works will be completed turning this airport into a benchmark among tourism-heavy airports on the Mediterranean. It is a stellar project in which ULMA has collaborated supplying pre-cast systems for Drainage and Cable ducting for the installations.

The large increase in passenger numbers at the Malaga airport in recent years drove AENA to embark on this extension to adapt it to the growing demand of tourism. It is part of Malaga Plan, an ambitious project with an investment of 1.775 million euro which has involved, among other things, the construction of a new terminal building and the extension of the Malaga Airport air field. Engineering company INECO was contracted to run the extension project for the air field, which included the construction of a second air strip of 3,090 meters and 14º of divergence in respect to the current runway.

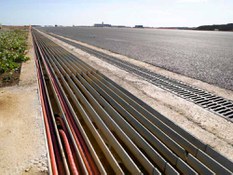

Drainage system

In a project with these characteristics, the drainage system is a key factor both to drain surface water from the runways and to guarantee its resistance to heavy loads. The Malaga Airport entrusted the new air field runway drainage system to ULMA Architectural Solutions, which has supplied more than 20,000 ml of its drainage channels with cascade slope and a 2.5% presloped.

Channels with incorporated slope are the only type on the market with a real 2.5% slope, which, thanks to their marked incline provide greater hydraulic capacity and overcome the serious limitations on slopes but provide what an airport requires to drain its runways, making them the ideal product for this kind of construction. Likewise, the channel grate has been completed with F900 floor grates in accordance with the Standard EN-1433.

Cable ducting system

Furthermore, ULMA has also supplied more than 40,000ml for the beacon cable ducting and guiding system. This is a system of pre-cast slabs of polymer concrete, essentially comprised of plate, cable tray, transformer connection box, and ductile iron covers.

The Peine ULMA Line, is the only patented beaconing system on the market, and has 5 completely independent taxi-ways in service, through which the primary cables are ducted. The separations between the taxiways have been designed so that in the case of any possible short-circuit in one of them, the normal operation of adjacent services is not affected.

The ULMA AL12F sump unit stands out for its light design and has an interior tray for transformers. The ductile iron covers are designed to take loads up to F900 according to Regulation EN-1433. Different to other solutions found on the market, ULMA tests the set comprised of the sump unit and cover, guaranteeing a perfect result for the entire system.