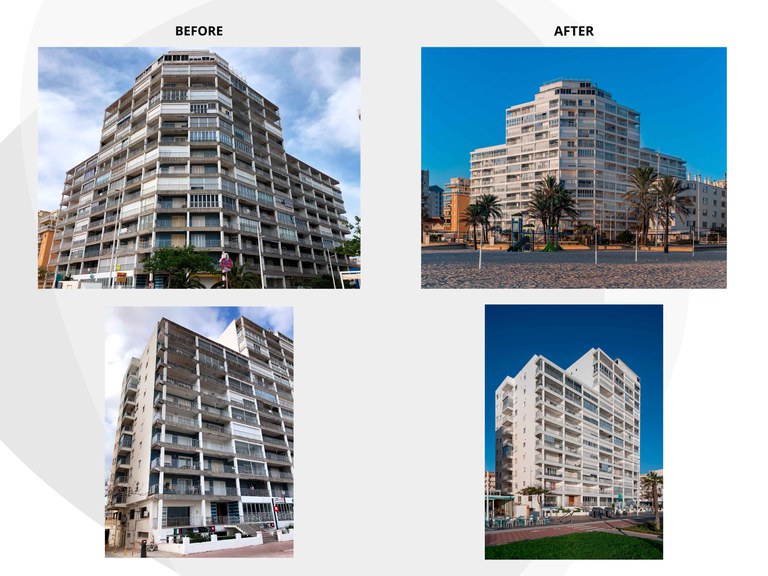

Renovation Of The Bonaire Building On Gandia Beach

We all have muses that inspire us at different points of our lives. They help to guide us along the right path to our objectives.

A while ago I was chatting with Jordi García Miragall, the architect responsible for renovating the Bonaire Building, and he mentioned how he had discovered ULMA and its customized precasts thanks to an influential architect he knew.

The Santa María building was renovated in the early 2000s. Ignacio Lafuente Niño, the project manager, needed to replace the terrace slab faces that had become deteriorated by carbonation and saltpeter. Jordi G. Miragall was particularly surprised by ULMA’s ability to personalize terrace slabs in rounded shapes for the project. It was for that reason that he chose ULMA for the Bonaire Building renovation project.

Bonaire, right on the beach.

If you need a custom precast for your project, contact us here.

The saline environment and ambient humidity are the most common causes of deterioration in beachfront facades. This impressive curved building with sea views had become lackluster due to salt air corrosion and the passage of time. It was designed back in the 70s by the architect Rafael Rivera, so its original 1-meter wide slab fronts needed to be replaced by precasts, replicating the L shape of the original slab faces. And this time they wanted to use a salt-resistant material, so Stoneo was perfect. Thanks to its waterproof design, water is unable to penetrate the panels, making them resistant and long-lasting even in the most corrosive environments.

The renovation project was carried out in two stages, repairing the damage to the primary facade, and the cracks and crevices caused by the previous renovation. The parts to be replaced were large in size, with a width of 1 meter and a 70 cm downwards overhang. They were not easy to handle so, to simplify the process, the width of the slabs was adjusted to X cm.

Photos are the best way to show the difference that the ULMA Stoneo precast facade slabs made to this renovation project. It’s quite astonishing.

That is more than just a simple facelift. It is a resistant and long-lasting improvement that will continue to look fantastic for years to come.

Coating and J-Max Joints: Minimizing the need for maintenance

At ULMA we offer various options that can be incorporated into projects, to simplify and minimize the maintenance work required for any building. For example, we offer the option to coat precast to make them more resistant, particularly to the effects of solar rays. The passage of time leaves it mark on everything, but this treatment helps to make ULMA parts last longer.

Another option we offer is the J-Max joint, a revolutionary solution to avoid damp that can occur in the joints between parts. It helps to drain rainwater to the outside, preventing it from leaking into the expansion joints that are required for precast installations. It works similarly to a small trench drain installed between the parts.

Both options have been used in this renovation.

Advantages of ULMA personalized PRECAST

- Personalization. It is possible to replicate the existing parts when renovating a building.

- Resistance. They are made using Stoneo, a material that absorbs almost no water at all, making it practically waterproof.

- No rust. Since there is no reinforcement inside the panels, there is no carbonation.

- Anti-corrosion. They are highly resistant to salty environments and pollution.

- Easy to handle. The panels are lighter than those made with traditional concrete or natural stone.

- Durability. J-Max protects the joints so they age better over time.

- Reliability and experience. We have been renovating buildings with precasts for over 30 years.

Working with durable parts that are easy to handle provides peace of mind. The renovation successfully updated and protected the building, extending its service life and modernizing its architecture, while maintaining the original Mediterranean character of the old building.

TECHNICAL DATA SHEET

- PROJECT: BONAIRE BUILDING, Passeig Marítim Neptú, Gandía

- ARCHITECT TEAM: MIRAGALL + ROMAGUERA

- CONTRACTOR: Construcciones BAÑULS

- ULMA PRODUCT: Customized SLAB FACES IN L SHAPE

- COMPLETED: 2023

- PHOTOGRAPHER: Josema Cutillas

We are extremely proud to be chosen as a result of our years of experience in similar projects.